|

Heat Blocking Materials

Core material for eco-friendly construction and high energy efficiency

Glass is widely used in the exterior wall considering the prospect right and design in the modern construction. However, the glass finishing of exterior wall increases the inside temperature in summer due to the inflow of sun heat, causes heat loss in winter, and as a result, brings about considerable energy losses. Considering this point, K&P Nano Inc. made excellent effective IR heat blocking material in terms of saving energy loss of glass, daylight, securing prospect, and design. We produce main material to process of various heat blocking complete goods for pleasant environment and high energy efficiency.

Kind and Features of Material

Materials for IR heat blocking include ITO, ATO, CTO, V-Pigment and Solution and those materials, great in transparency to coat with compounds of ITO, ATO and CTO over glasses or films, are available to be extensively applied to industry and living. CTO is, especially, the new nano material that our company, K&P Nano Inc., developed with our own original composite techniques in 2011; it shows high efficiency in rather small amount, compared with other existing materials such as ATO, etc.

Electrical, Electronic Materials

Core materials to secure antistatic and transparent conductive features!

By using nano powder, nanomaterial, which is the core material securing conductivity and transparency, is the one that enables to have electrodes shutting off electromagnetic waves or heat harmful to human body, and applies to glass or film which need antistatic effect, transparency and conductivity.

Sort and Feature of Material

Electrical and electronic materials include ITO, ATO, CTO Powder, Solution, and those materials, characterized by great in transparency, used as the electromagnetic shield or antistatic by making them have conductive electrodes, are available to be extensively applied to industry and living.

ITO

ITO, acronym for Indium Tin Oxide, is used to block electromagnetic waves harmful to the human body by coating with the ITO compounds over glasses or films to have conductive electrodes. ITO, marked by both features of great in transparency and outstanding as the electromagnetic shield, is broadly applicable to the electronic field and our daily life such as Braun-tube, LCD, PDP, organic EL, PET film, lens, glasses.

Application

LCD, PDP, CRT Monitor, PET PC Film, Glass, Ink, Functional film, IR film etc.

Process

Coating, Compounding

Product Type

Make to order system by customer's request on solvent and density

Solution

| Appearance |

Blue color, Yellow |

| ITO Content(%) |

30~50 |

| D-Particle(nm) |

50~100 |

| D-Base |

Water, O-Solvent |

| Conductivity(Ω/cm²) |

1.0x10β~10¹² |

| VLT(%) |

Min 70 |

| Hardness(H) |

2.0 |

| Haze(%) |

Max 1.0 |

| Mix-Resin |

Acryl, PU Resin |

| Coating Method |

IR, UV |

| Substrate |

Acryl, PET, PC, PMMA, TAC etc. |

Powder

| Appearance |

Blue, Yellow color |

| Assay(%) |

99.995 |

| SnO2(%) |

5~15 |

| P-Particle(nm) |

20~40 |

| D-Distribution(nm) |

50~100 |

| BET(m²/g) |

35 |

| Conductivity(Ω/cm) |

1x10-2 |

| D-Base |

Water, O-Solvent |

| D-PH |

3~10 |

| D-stability(day) |

120 |

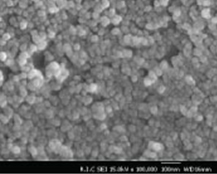

ATO

ATO, making holes by combined structure added with, as the dopant, Sb having +3 charge between Sn lattice having +4 charge, to transmit electrons through the holes, is the positive semiconductor structured material; nano ultrafine powders are not only available as the transparent conductive material which is not resistant against the other semiconductor materials, but also variously applicable, when dispersed into the homogeneous solid solution, to the field which needs antistatic and transparent conductive features, such as display panels, glasses, and plastics.

Application

LCD, PDP, CRT Monitor, PET PC Film, Glass, Functional film, IR film etc.

Process

Coating, Compounding

Product Type

Make to order system by customer's request on solvent and density

Solution

| Appearance |

Blue color |

| ATO Content(%) |

30~50 |

| D-Particle(nm) |

50~100 |

| D-Base |

Water, O-Solvent |

| Conductivity(Ω/cm²) |

1.0x10β~10¹² |

| VLT(%) |

Min 70 |

| Hardness(H) |

2 |

| Haze(%) |

Max 1.0 |

| Mix-Resin |

Acryl, PU Resin |

| Coating Method |

IR, UV |

| Substrate |

Acryl, PET, PC, PMMA, TAC etc. |

Powder

| Appearance |

Blue color |

| Assay(%) |

99.995 |

| SnO2(%) |

Max 20 |

| P-Particle(nm) |

5~10 |

| D-Distribution(nm) |

10~30 |

| BET(m²/g) |

49.4 |

| Conductivity(Ω/cm) |

1x10 |

| D-Base |

Water, O-Solvent |

| D-PH |

3~10 |

| D-stability(day) |

120 |

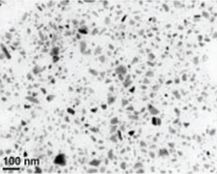

CTO

CTO, making holes by combined structure added with, as the dopant, Sb having +3 charge, Sn having +4 and Cs having +1 charge between W lattice having +6 charge, to transmit electrons through the holes, is the positive semiconductor structured material; nano ultrafine powders, dispersed into the homogeneous solid solution, featured by blocking near-infrared rays, show outstanding functions, compared with the visible transmittance of ATO and ITO.

Application

LCD, PDP, CRT Monitor, PET PC Film, Glass, Functional film, IR film etc.

Process

Coating, Compounding

Product Type

Order production by request of customers, By solvent, Density

Solution

| Appearance |

Blue color |

| CTO Content(%) |

10~20 |

| D-Particle(nm) |

50~100 |

| D-Base |

O-Solvent, H2O |

| VLT(%) |

Min 70 |

| Hardness(H) |

2 |

| Haze(%) |

Max 1.0 |

| Mix-Resin |

Acryl, PU Resin |

| Coating Method |

IR, UV |

| Substrate |

Acryl, PET, PC, PMMA, TAC etc. |

Powder

| Appearance |

Blue color |

| Assay(%) |

99.995 |

| SnO2(%) |

5~15 |

| P-Particle(nm) |

20~40 |

| D-Distribution(nm) |

50~80 |

| BET(m²/g) |

35 |

| Conductivity(Ω/cm) |

1x10-2 |

| D-Base |

Water, O-Solvent |

| D-PH |

3~10 |

| D-stability(day) |

120 |

|

|

New Nanomaterial

New Nanomaterial

IR (Heat blocking)

IR (Heat blocking)

New Nanomaterial

New Nanomaterial

IR (Heat blocking)

IR (Heat blocking)